Back Brucheinschnürung German گردنی شدن Persian Strizione Italian Insnoering (materiaalkunde) Dutch Estiramento (engenharia) Portuguese Boyun verme (Mühendislik) Turkish 頸縮 Chinese

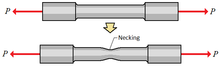

In engineering and materials science, necking is a mode of tensile deformation where relatively large amounts of strain localize disproportionately in a small region of the material. The resulting prominent decrease in local cross-sectional area provides the basis for the name "neck". Because the local strains in the neck are large, necking is often closely associated with yielding, a form of plastic deformation associated with ductile materials, often metals or polymers.[1] Once necking has begun, the neck becomes the exclusive location of yielding in the material, as the reduced area gives the neck the largest local stress.

- ^ Kinloch, AJ; Young, RJ (1995). Fracture Behaviour of Polymers. Chapman and Hall. p. 108. ISBN 9789401715966.